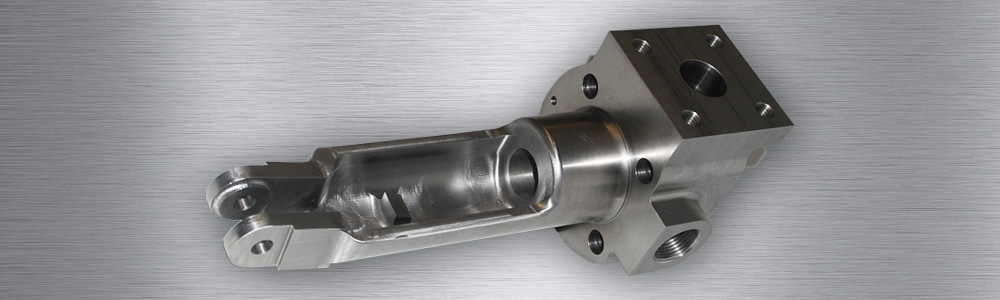

Reinforce

- Metalworking in the highest quality, combined with modern technology.

- React quickly, producing cost-effective, delivering on time, meet the individual customer requirements - from prototype to series part.

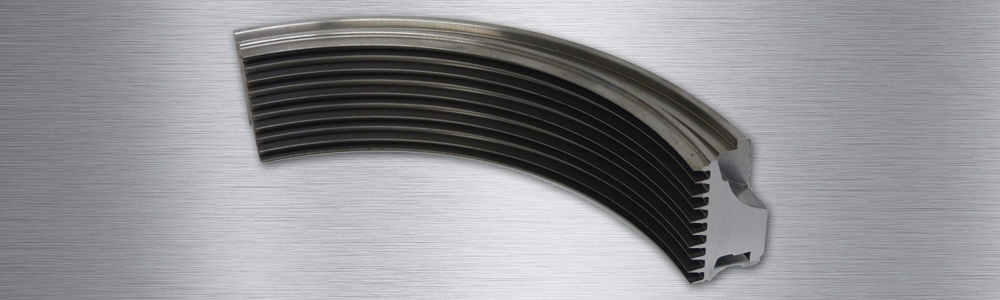

- On the other hand, it is possible for us as a rule, to cover even a very short-term needs of our customers on time and with consistently high product quality.

- From incoming material to final product are subject to our production parts to a strict quality control. Selected suppliers are having their good name for the quality of their products.

- Motivated, qualified and always in use, all staff are confident behind the quality they produce. After consultation, our customers for material material certificates, Inspection Certificate and for the manufac-tured parts measurement protocols for quality assurance verification. By constantly adapting to the latest production methods and by training our staff, we can meet all future requirements.

- The management and our employees are committed to the interests of its customers and of environmental protection, stringent quality policy.